Clamp Meters 101

Clamp meters offer a range of capabilities to tackle everything from basic DIY electrical repairs to heavy-duty industrial predictive maintenance.

What are clamp meters?

Most clamp meters take the front-line electrical diagnostic testing capabilities of a digital multimeter (DMM) and add a dedicated set of jaws that can be clamped around a wire or busbar for non-invasive current measurements. While multimeters can take contact amp readings up to 10 A using test leads, clamp meters offer safer, non-destructive current readings in ranges up to 3000 A.

How are clamp meters used?

Clamp meters can be used as a multimeter to connect to electrical circuits to measure voltage, current, frequency, capacitance, temperature, and resistance using test leads (as well as testing for continuity in a circuit to see if something failed or is missing in the circuit).

What sets them apart are their distinctive, springloaded jaws that can be opened using a side-mounted trigger. They can clamp around one or multiple conductors to easily take current readings. Clamp meter jaws are available in various sizes, with larger jaws accommodating conductors with wider diameter.

Some measure AC current – originating from public utilities—while others measure DC current. DC current can be converted from AC for industrial DC motors, but it can also come from battery-powered sources, vehicle systems using DC, and solar power arrays. Top-of-the-line clamp meters usually measure both AC and DC current.

Some clamp meters are single-purpose, current-only meters, trading other functions for smaller jaws, higher resolution readings, increased sensitivity, and an overall compact pocket-sized design. Others have a “flex clamp” flexible loop in place of jaws. The long pliable loop can be manually snaked around crowded cables in a cabinet that might be difficult to access using rigid jaws.

Flex clamp meters make it easy to wrap around wires or busbars.

Advanced clamp meters offer advantages that provide better accuracy for more challenging jobs. “True RMS” (Root Mean Square) clamps ensure accuracy even when electrical waveform quality isn’t a clean sine wave. “Inrush” mode takes a snapshot of the surge of current when equipment is first started up.

When wires are bundled close together coupling can cause stray (or “ghost”) voltages leading to inaccurate readings. A “LoZ mode” can eliminate the error. Industrial sites with variable frequency drives (VFDs) also demand a “Lo-Pass” filter mode to improve accuracy.

Select models also measure temperature with a pointand-shoot, no-contact infrared thermometer built in. Others use dual thermocouple inputs to calculate a temperature differential (“delta-T”), which is indispensable for HVAC/R work.

Dual thermocouple probe inputs offer one-button access to Delta-T.

Premium clamp meters with Bluetooth® or METERLiNK™ can even stream readings to a mobile device with remote viewing apps for safer, remote monitoring.

Where are clamp meters used?

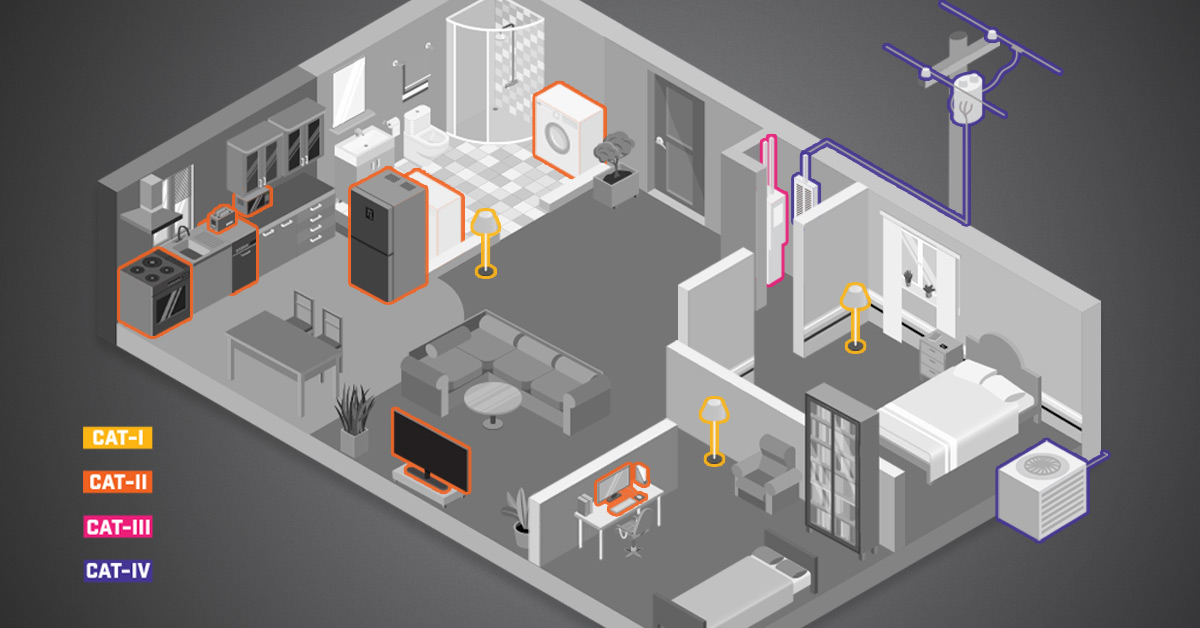

First, check a clamp meter’s overvoltage category rating (“CAT” for short) to see where it can be used. CAT II meters can be used on plug-in devices and appliances, while CAT III can be used inside buildings on fixed wiring. The most robust category, CAT IV, is for service panels and low-voltage outdoor wiring coming from the utility. For safety, always factor in potential work needs, and go with the best CAT rating. Clamp meters can measure current loads on circuit wiring and equipment including motors, pumps, lighting, sensors and switches. They are found everywhere from DIY toolboxes to industrial maintenance tool carts.

Built-in work light illuminates dark job sites

Who uses clamp meters?

Basic clamp meters are used by do-it-yourselfers to fix car electrics, appliances, lighting, and wiring around the house. Electrical contractors use them for new installations and repairs. Similarly, HVAC and refrigeration technicians use them to test electrical components in their systems. In industrial plants, clamps are used by predictive maintenance technicians to ensure equipment continues working.

Which clamp meter is right for me?

Choose a clamp meter with capabilities matched to your job’s needs. Professionals should opt for True RMS meters. Think about typical sites and the equipment you work on; look for the features listed above and the amp rating that match your needs. Consider adding new features you hadn’t considered that might make your job easier, such as delta-T for HVAC work, or wireless readings that display on your mobile device so you can step away from energized equipment.